![]()

Flexcarbon®

Making the Impossible, Possible, the CFRP Revolution.

High-performance Materials that Snuggle up to People

Application Example

The new Flexcarbon chair “CALLU” is

designed by designer TOSHIYUKI KITA,

who took full advantage of the material’s

characteristics. The product symbolizes

a new style of chair manufacturing with

consideration of the sustainability aspects.

“CALLU” was unveiled on April 17th at the

Milan Desin Week, ddn Hub [FUORISALONE].

[Crick here of details!]

About Flexcarbon®

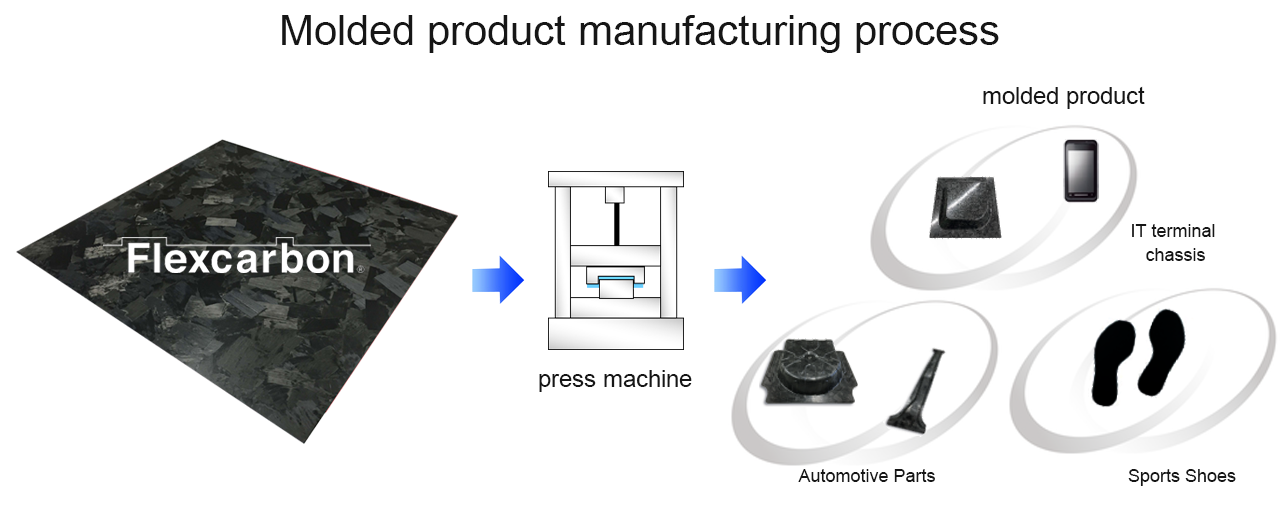

Mass production that could not be achieved with conventional carbon fiber composite materials can be achieved with the simultaneous forming of complex shapes and high strength through the use of thermoplastic CFRTP sheets.

— There are 4 Functions —

Entering into an era where previously impossible shapes are now possible!1. Complex Shape Formability

Flexcarbon® makes it possible now to make shapes that could not be made before by press molding complex shapes, for example, shapes of uneven thickness, honeycomb shapes and others can be made. Considering the requirements of our customers we propose two molding methods that will lead to mass production.

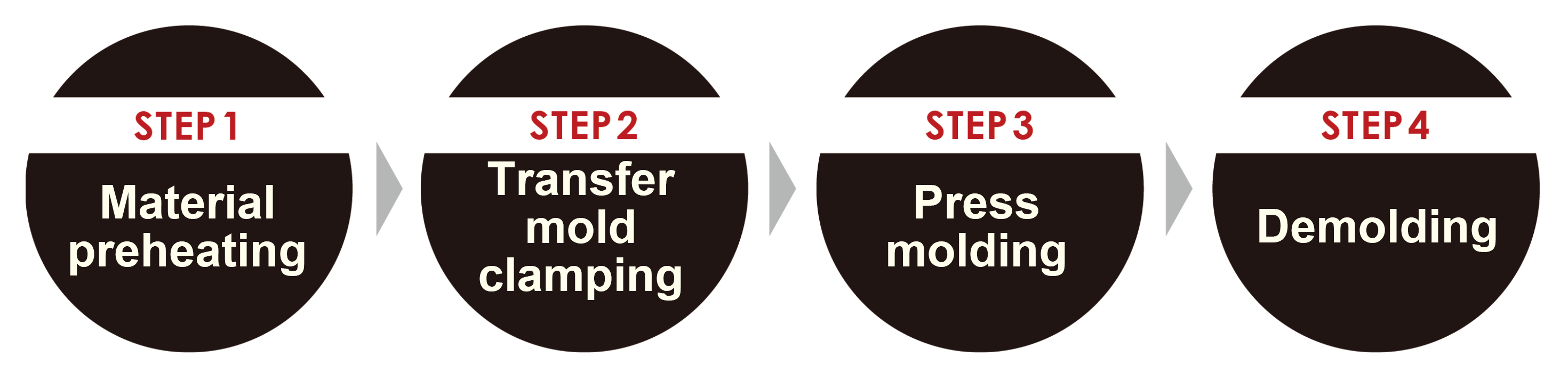

< 1. Stamping Molding >

Preheat the material, 1 minute high-cycle molding by cold press method possible. Development of new high flow material capable of forming complex shapes.

< 2. Heat & Cool >

Heat the mold; improve material flow, by filling in the material (fiber and resin) to the tip of a fine complex shape, mass production is achieved through.

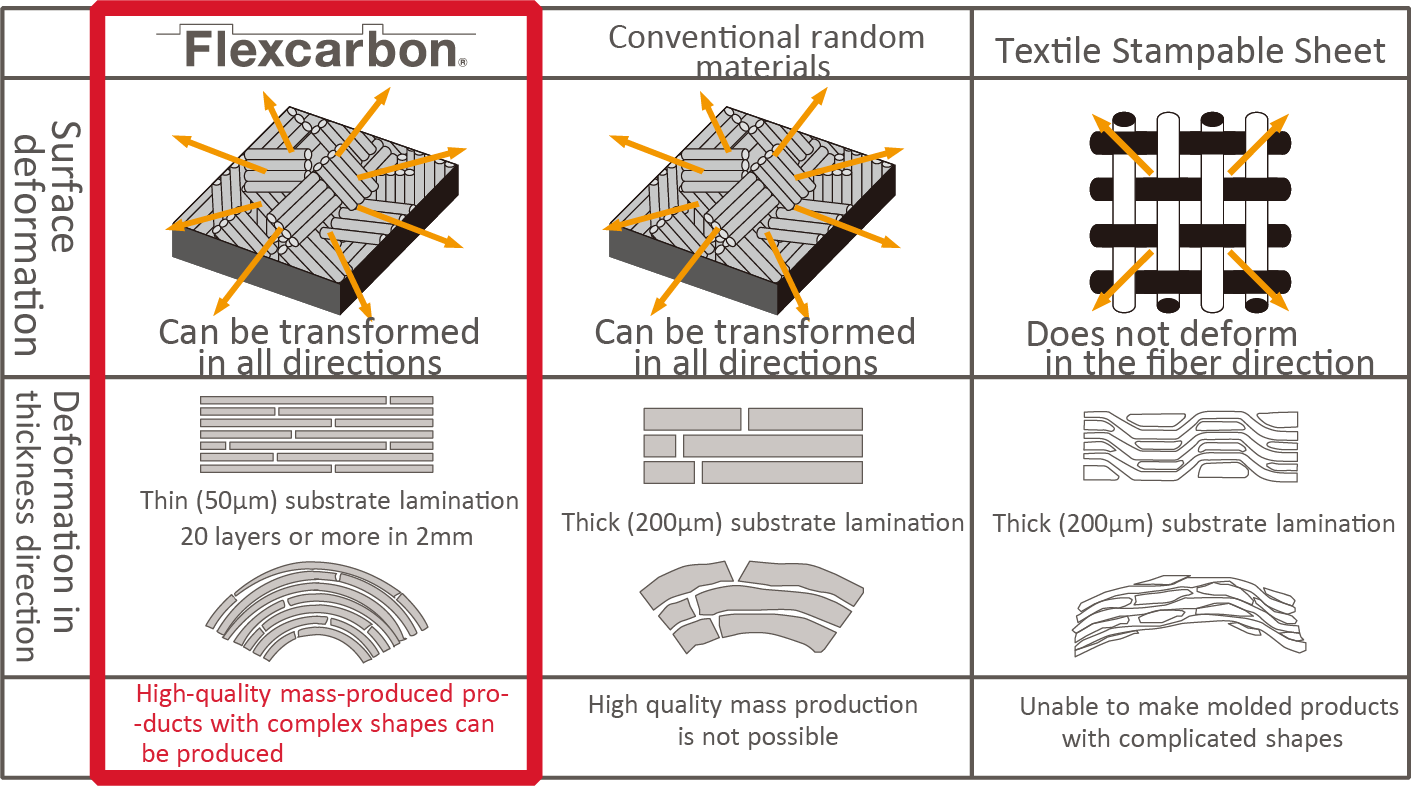

2. Isotropic and Physical Stability

Using void-less thin layer tape material, with unique lamination technology, high strength and isotropy can be obtained, and with this homogeneous material olding process, excellent productivity is possible.

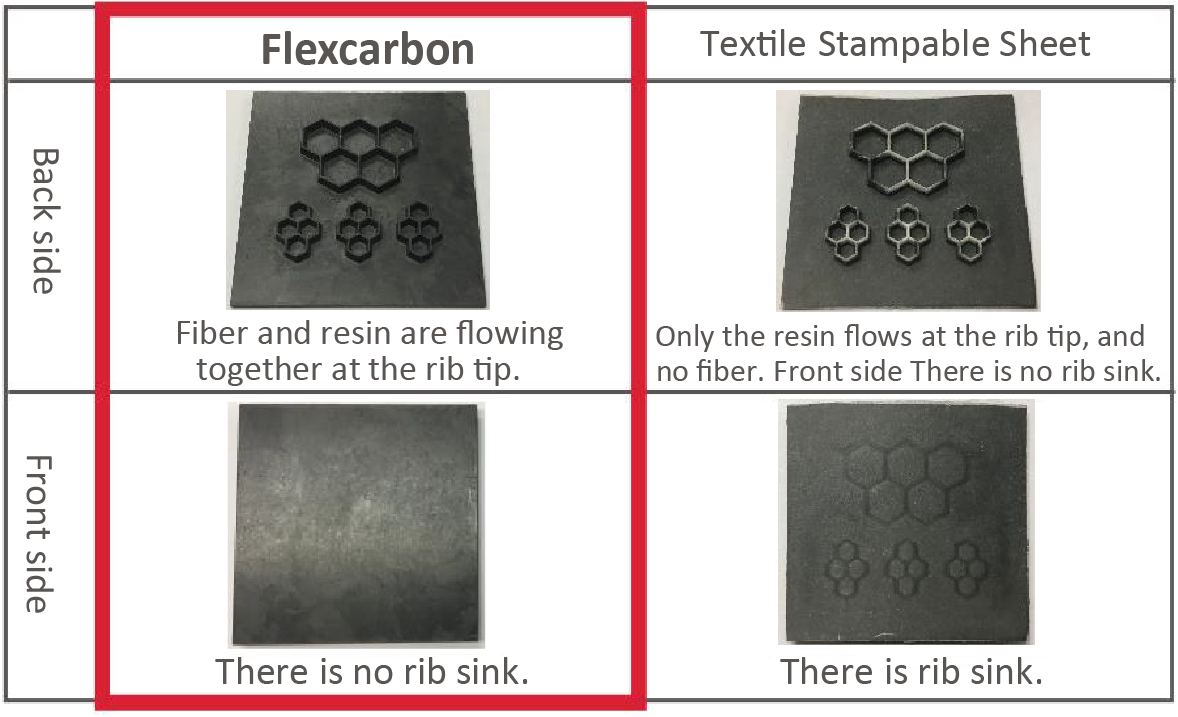

3. Free Formability by Means of Thin and Multilayer

By means of the spreading of carbon fiber by unique fiber separation technology, 50μ ultra-thin layer is achieved. The thin and multi-layered void-less tape material, made by impregnation technology, enables the production of molded products with little uneven thickness, complicated boss and rib structures, and with few sink marks on the exterior surface. Highly flexible design and strength design are possible.

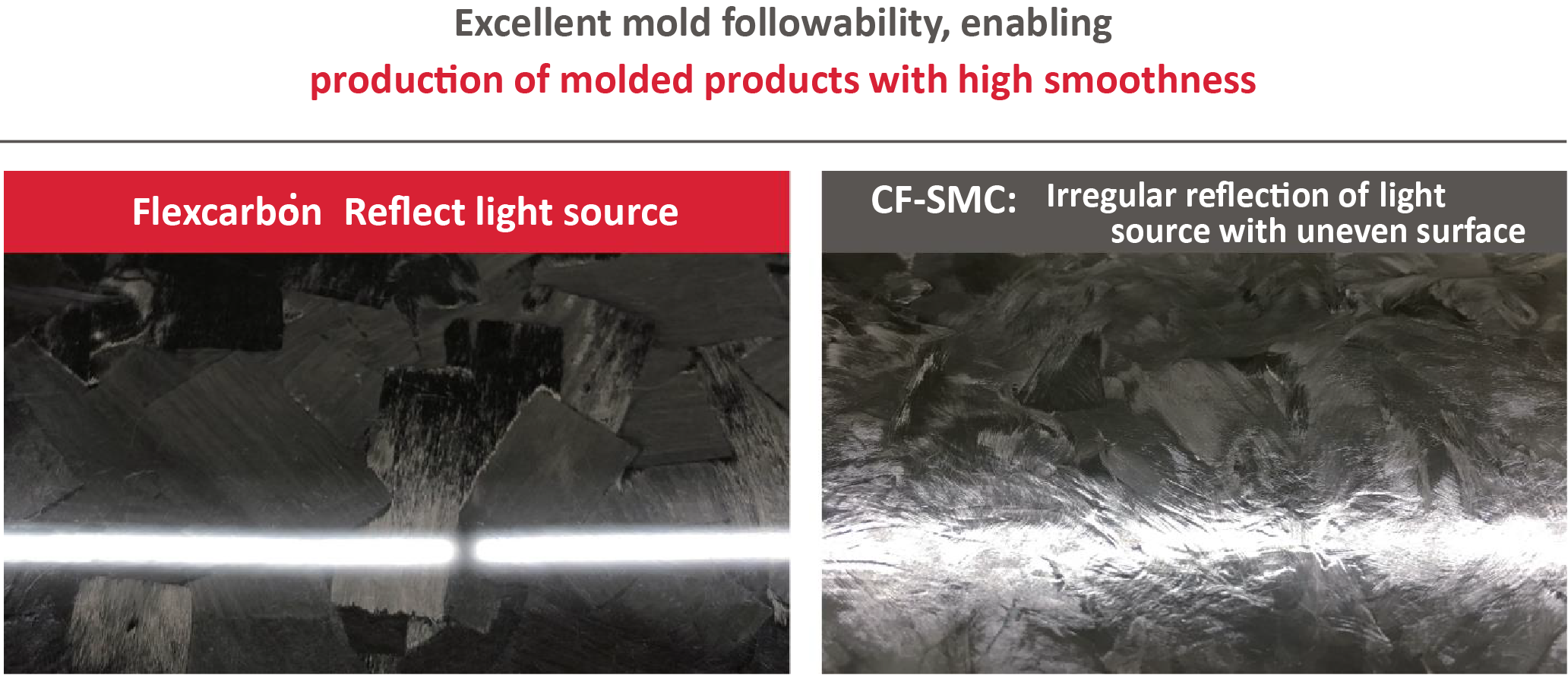

4. Surface Smoothness

Excellent mold followability, enabling production of molded products with high smoothness. With spread thin layer tape and thermoplastic epoxy, it is possible to manufacture molded products with excellent mold following properties and high surface smoothness. There is good adhesion to paint, so no need for post-processing polishing.

Download

Introducing the four functions of Flexcarbon®

The above four functions are in a brochure.

Download from here.

![]()

METASPRINT(ASICS Japan)

METASPRINT(ASICS Japan) archelisFX(archelis)

archelisFX(archelis) CFRP Guitar(Secca)

CFRP Guitar(Secca)